Introduction of the Robotics Solution in iPhone Manufacturing

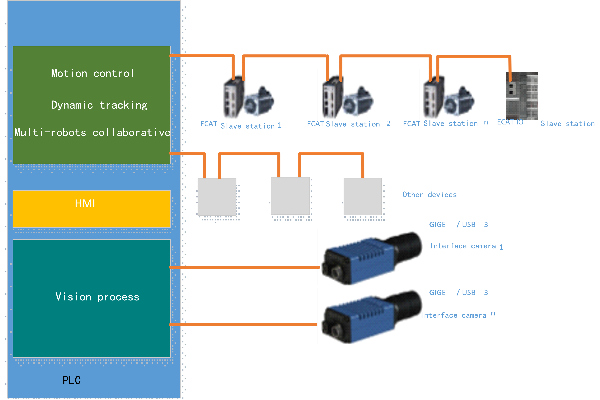

The iPhone manufacturing process involves a complex set of procedures that require high precision and accuracy. One of the key components that ensure the quality and reliability of the iPhone is the vision system of robotics solutions. In this article, we will explore how the vision system of robotics solution works in the iPhone manufacturing process.

Firstly, let’s understand what the vision system is. It is a type of robot system that uses cameras and image processing algorithms to detect, inspect, and analyze objects. In the iPhone manufacturing process, the vision system is used to inspect various components of the iPhone, such as the camera lens, screen, and internal circuitry.

The vision system is integrated into the assembly line, where the iPhone components are assembled by robots. As the components move along the assembly line, the vision system takes images of them and processes them in real-time. The system uses various image processing algorithms to identify defects, such as scratches, cracks, and misalignments.

Once a defect is identified, the vision system sends a signal to the robot to correct the problem. For example, if the vision system detects a scratch on the iPhone screen, the robot will use a polishing tool to remove the scratch.

The vision system of robotics solution is critical to the quality and reliability of the iPhone. Without it, defects and flaws in the components could go unnoticed, leading to a lower quality product. The vision system ensures that each iPhone meets the high standards of quality set by Apple.

Example of the Vision System in the iPhone Manufacutring

Let’s take a look at a specific example based on our current technology.

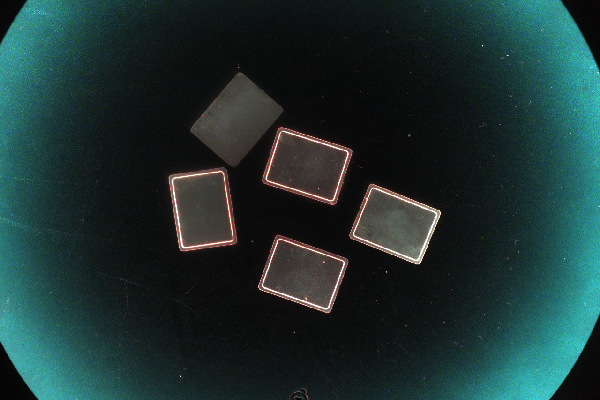

The number of inspection stations:

Currently, only one piece of glass can be inspected at a time

Detection target:

Flat mobile phone cover glass (not 3D glass)

Detection accuracy:

Dimension detection accuracy, the maximum deviation is ±0.0029mm, the average deviation is ±0.00148mm. Arc detection accuracy, the maximum deviation is ±0.0369mm, and the average measurement deviation is ±0.01595mm.

Platform movement accuracy:

1um

Number of stopping points:

26

Testing time:

The detection time is the total time for the movement to cover all stops and obtain the detection result. The maximum time is 15.52s, the average time is 14.28s.

Operating procedures:

1) Set the allowable deviation range of each test item

2) Place the standard glass sheet on the inspection table, and run the “standard sheet parameter extraction” program, the system automatically saves the parameter value of the standard sheet

3) Place the test glass sheet and the inspection table, and run the “glass inspection” program

4) The system automatically calculates the parameter value of the test glass, and compares the test result with the recorded value of the standard glass

5) For each test item, the mark whose test result meets the allowable deviation range is normal, and the mark that deviates from the allowable deviation range is abnormal.

6) Transmit the test results to a third-party system through communication

Conclusion of the Robotics Solution Vision Technology in the iPhone Manufacturing Process

In conclusion, the vision system of robotics solution plays a crucial role in the iPhone manufacturing process. Its ability to detect and correct defects in real-time ensures that each iPhone meets the high standards of quality set by Apple. With the use of advanced image processing algorithms and robotics technology, the vision system has revolutionized the way iPhones are manufactured.